A few months ago, PTC asked Creo users to submit their best work for a Product Design Contest. Submissions came from more than 60 countries and included objects like a wooden bike, a modular lamp, and jewelry inspired by sunflowers—all made with Creo product design software.

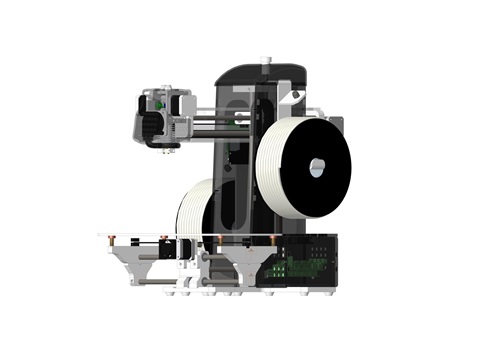

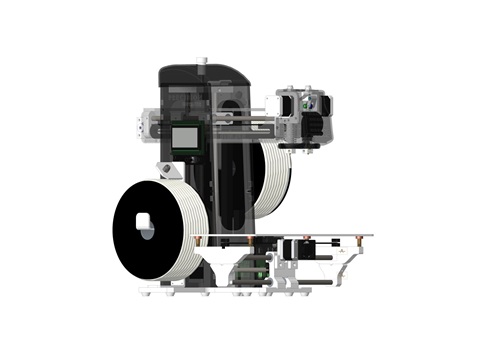

One of the finalists in the contest was experienced product designer, Mr. Muthalpandy Muthirulappan. He created a low-cost 3D printer that produces accurate and affordable prototypes. What’s better? Mr. Muthirulappan used 3D printing, or additive manufacturing, to troubleshoot his own printer design!

Mr.Muthirulappan, a finalist in the PTC Product Design Contest, designed a low-cost metal 3D printer. “Low cost” refers to a range of printers priced from $1000-2500 USD.

Location: India

The design: Mr. Muthirulappan’s 3D printer has several notable features:

The printer’s smooth rods are customizable. You can change the size and length.

The design challenges: Mr. Muthirulappan faced several challenges in creating his design:

The solutions: How did Mr. Muthirulappan overcome the 3D printer’s design challenges? He created a 3D printed prototype of his model, of course!

“I printed all of the main components, assembled it, and ran the machine to simulate the real printer,” he said. The prototype worked really well, but the printer’s vertical axis needed to be tweaked. Each axis has two smooth rods. However, he ended up adding a third rod along the vertical axis for additional support.

Mr.Muthirulappan said, “My 3D printer is designed to compensate for pitching, rolling, and yawing forces along the three axes.”

Why Creo? Mr. Muthirulappan raves about Creo, saying, “Solving any design problem is much easier and faster compared to other CAD software.” Here’s how it helped him:

Creo 4.0 thoughts: Mr. Muthirulappan created his design using Creo 3.0, but said of the new release, “It seems like that many things in Creo 3.0 have been simplified in the Creo 4.0.”

Any advice for someone trying to create their own winning design with Creo? Mr. Muthirulappan said he learned a lot about how to improve his design when he analyzed the 3D printed model. So, his advice for other designers is simple: Create a 3D model that is 3D printable. Then, assemble the printed model as a functional prototype. Also, use Creo’s 3D print applications, which help analyze the model for any thin sections and continuity and tangency of the profiles.

No matter what you want to create, Creo 4.0 can help you develop stellar designs. Packed with hundreds of enhancements, this release is easier to use than ever, and includes tools for better 3D printing and model-based definition. Visit the Creo 4.0 page to find out more and start using it today.

©Copyright 2024. All rights reserved by Modelcam Technologies Private Limited PUNE.

Image Courtesy : PTC