In 1989, camera maker Canon caused a controversy with an ad campaign that featured bad-boy tennis player Andre Agassi and the tagline “Image is everything.” That was the whole controversy--the idea that the way things look is really important. In today’s era of Instagram, Snapchat, and selfie sticks, can you imagine that causing a stir?

As a product designer you know image matters a lot. Your products have to function well, but form is often critical to their success, too. That isn’t conjecture. It’s been studied and documented. The Hitachi Design Center asked 252 people to test 26 variations of an ATM design. The study participants were more likely to rate the product as easy to use if they liked the way it looked, whether or not that was true of the way they actually used the product. An academic study published in the journal Applied Economics gave teenagers simulated cell phones and found the same thing--the kids thought the better-looking phones were easier to use.

The aesthetics of your manufactured designs rely heavily on what their surfaces look like. Modern surfacing tools that work with the design software you already use make designing surfaces easier than ever. Here are six reasons why these tools are essential to successful design.

You can’t do what you do without parametric modeling, but sometimes you need the flexibility you can only get from using freeform geometry. Surfacing tools give you that freedom and flexibility inside your parametric design software, so you can build freeform geometry at any point in the design project. Surfacing tools let you use as few or as many constraints you need to.

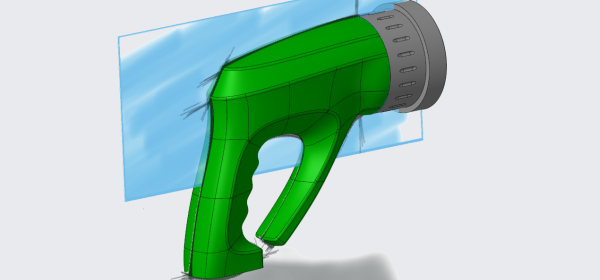

A concept created using Creo Sketch and Freestyle in Creo Parametric.

How can you model a surface without curves? Curves are where surfacing tools really shine. Surfacing tools give you full control over the degree of curves, and they let you move control points dynamically or numerically. You can edit multiple curves simultaneously, view the original curve while you’re editing, and connect curves and surfaces with positional, tangent, draft and curvature continuity.

When you use Creo’s surfacing tools, you can work within a four-view window that lets you see your design from multiple angles. You can also reference defining geometry such as points, planes, axes, curves, surfaces, and solids. And because surfacing tools are fully associative, your surfaces and curves will be updated when you make changes to the rest of your design.

Curves can get tricky to work with. Surfacing tools aim to make curves much simpler for you to manage and manipulate. They let you make automatic surface connections and easily modify the connection type: tangent (G1), curvature (G2) or acceleration (G3). Because they support n-sided surfaces and re-parameterization of surfaces, they help you design curves much faster. Surfacing tools also regenerate surfaces in real-time, make automatic surface connections, and change surface types between boundary, loft, and blend while maintaining all reference. Doesn’t that sound better than the way you’re working now?

BANG Designers used the Creo ISDX extension to create the Moonwalkr helmet. Lighter and better ventilated than other helmets on the market. And, yes, it looks fantastic.

Everyone wants good-looking designs, but they also have to be manufactured. Surfacing tools don’t require you to sacrifice function for the sake of form. Because they work with the design tools you already use, you can still get the same production and manufacturing documentation you can access with your existing software.

We can’t speak for anyone else’s surfacing tool, but Creo ISDX includes multilevel subdivisional modeling, which allows you to control even more of the surface. With Creo ISDX, you can create finer detailing without altering the existing shape of your design. We know how much design engineers like to dive as deeply into the details as they can.

More than 200,000 people like you have signed up for our monthly product newsletter, PTC Express. Join them today to get Technical tips, techniques and insider tricks, and much more.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.