PTC's Creo parametric 3D CAD solution allows you to create your best designs more quickly.

Because Creo offers completely integrated design, simulation, and manufacturing capabilities, manufacturers rely on it to get the most out of their CAD system.

Creo offers model-based product creation, generative design, real-time simulation, and effective composites and additive and subtractive manufacturing techniques.

Simple core modeling techniques contribute to daily productivity gains.

Changes are automatically spread throughout the value chain since Creo is fully associative.

With 85 improvements, Creo+ now offers all of Creo's advantages through SaaS, enhancing daily design collaboration and efficiency. Improved file export capabilities and expanded model-based definition (MBD) provide consistent, reliable data. Utilize cutting-edge composite tools to create solid geometry from composite layers, and use AI-powered generative design for thermal optimization research. Flat assemblies and feature presets have been made accessible for improved usability based on user feedback. Last but not least, Creo+ updates 75% faster, and communication tools built into the design environment facilitate real-time collaboration so you can produce your finest designs quickly.

The improvements in Creo 12 will be covered in this on-demand webinar, along with an exclusive preview and examples of how Creo can help you produce your best ideas faster:

Enhancements to productivity and usability that you will utilize on a daily basis

Industry-leading precision and fidelity in composites design

Improved model-based definition (MBD) and detailing tools

Both generative and simulation-driven design

Cutting-edge equipment for additive and subtractive manufacturing

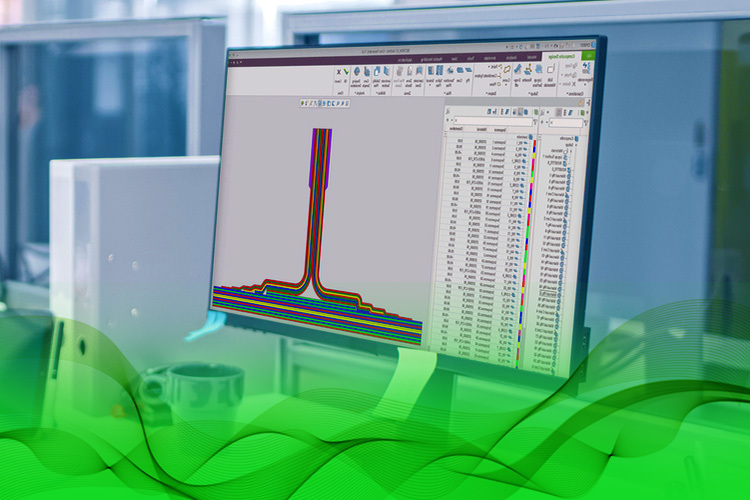

Design advancements for electric harnesses

Along with all the features of Creo 12, PTC's Creo+ SaaS solution will be covered, along with cloud-based collaboration and license management tools.

With 85 improvements, Creo+ now offers all of Creo's advantages through SaaS, enhancing daily design collaboration and efficiency. Improved file export capabilities and expanded model-based definition (MBD) provide consistent, reliable data. Utilize cutting-edge composite tools to create solid geometry from composite layers, and use AI-powered generative design for thermal optimization research. Flat assemblies and feature presets have been made accessible for improved usability based on user feedback. Last but not least, Creo+ updates 75% faster, and communication tools built into the design environment facilitate real-time collaboration so you can produce your finest designs quickly.

With cutting-edge tools that let engineers effectively design, model, and manufacture composite parts, Creo 12 offers industry-leading realism and accuracy in advanced composite structure design. Creo 12 can more rapidly and precisely create solid geometry from composite layers and provide an associative manufacturing reference model. You can now make more creative composite designs by merging plies from many zones. With its new, cutting-edge tools, Creo 12 provides the most dependable and scalable composite structure design capabilities available worldwide.

.jpg)

Creo's model-centric methodology guarantees that all product details are precisely specified in the 3D model, giving the appropriate information to the appropriate person at the appropriate moment. Creo 12 has better file export features. Annotations may now be reused more easily, and GD&T Advisor now supports intent surfaces and datum reference features. Engineers may produce their best ideas faster by using model-based methodologies with PTC's Creo 12.

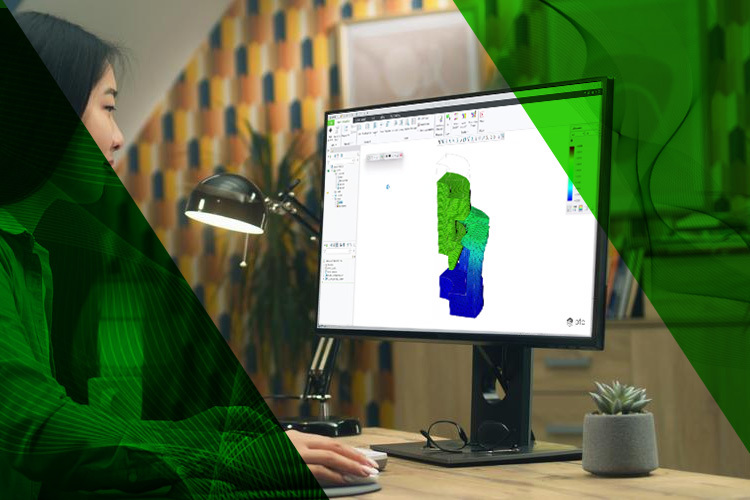

Using award-winning generative design and real-time Ansys simulation tools, Creo simulation-driven design assists engineers in iterating and optimizing designs at an early stage of the design process. Furthermore, engineers can do thermal optimization studies using Creo 12 employing AI-powered generative design in addition to structural and modal analysis. The findings of Creo Simulation Live and Creo Ansys Simulation have been made simpler and better by Creo 12's enhanced Ansys solvers (25R1). Engineers can create their best designs faster because of Creo's powerful simulation-driven design tools.

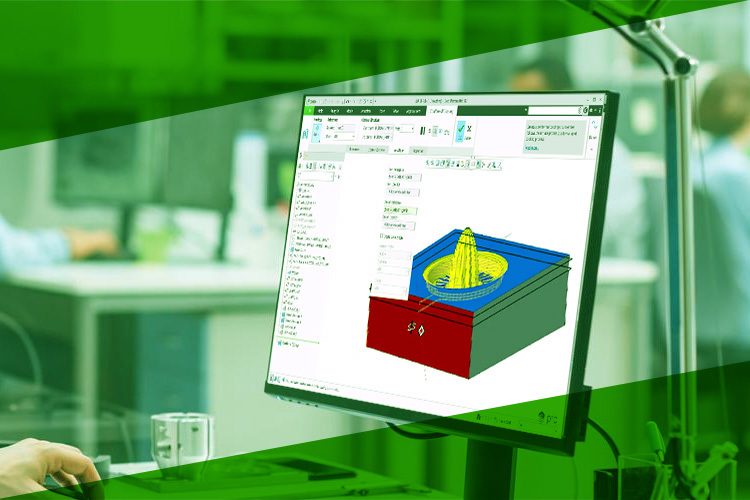

Creo is the ideal choice for designing for both additive and subtractive manufacturing. With Creo 12 and additive manufacturing, engineers can now create conformal cooling channels in injection-molded tools for optimal performance. Lattice customization and connection are further improved by additive manufacturing, while undercut high-speed milling has made subtractive manufacturing better than before. With Creo 12, engineers can create their best production designs more quickly.

©Copyright 2026. All rights reserved by Modelcam Technologies Private Limited PUNE.