The Industrial Internet of Things (IIoT) has been captivating minds across the globe, especially in recent years with the buzzword gaining mainstream. The plethora of potential applications in a connected world has driven widespread excitement. There has been lots of successes (see here, here, and here) but implementation has been a struggle for some companies. Many have found themselves in proof-of-concept purgatory.

In my experience, we’ve seen industrial organizations spend a considerable amount of resources in IIoT incubation zones and constructing never-ending lists of uses (we have had a customer say they had identified nearly 100 IoT use cases).

However, many of these IIoT projects have failed to escape pilots and make it into real-world production -- let alone drive value for the company as a whole.

We’ve found companies successful in their IIoT strategy and initiatives follow a few practical steps to find the IIoT ‘sweet spot’. The winning mindset is less about proof-of-concept and more so on proof-of-value. This minor shift in phrase generates massive impacts, which leads into how we think about deploying IIoT below.

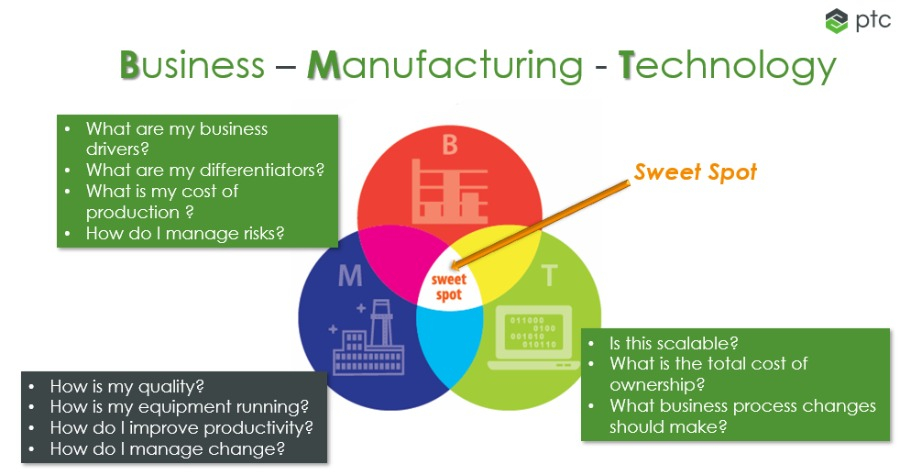

Our framework for implementing an IIoT strategy integrates three key areas: business, manufacturing, and technology:

A successful IIoT strategy looks at the opportunity through the broadest lenses possible, which stems from its short-and-long term strategic goals. CxO buy-in and sponsorship must be involved from early-on to look at this company-wide impact view and how IIoT will make the company successful year-over-year. This includes key stakeholders from both informational technology (IT) and operational technology (OT) to knock down cultural barriers and collaborate.

Once the pieces are in place, there needs to be some view of what the perfect version of the overall puzzle should look like. Meaning that IIoT success needs to be defined in short-term intervals within long-term visions; it is a journey, but value can be created and should be recognized in sprints.

Without a final destination in the IIoT journey in mind, companies typically run into ambiguous IIoT states with costs skyrocketing, and no exit or business value in sight. Waypoints to measure short-term success help keep the IIoT project on-the-rails and are culturally important for getting on-going support from within the organization.

These goals will roll up to the use case and technological goals but are importantly tied to outward-facing financial metrics (for example, x% increase in revenue) and/or internal ones such as operational efficiencies (x% increase in OEE, production volume).

There will be lessons learned, new objectives, and unanticipated events along the way with the ending IIoT strategy maybe taking a different form then once thought, but the range for unpredictable and malignant outcomes is significantly minimized when an IIoT journey is mapped, and connected to the strategic vision and business goals.

Every strategic goal for an organization will have some internal and external challenges. Weighing these challenges is needed along with the potential measurable impact and time-to-value to ultimately generate the use case(s) with the best chance of success. There are innumerable factors that must be considered in any given use case but mapping them to the greatest extent as possible is critical to IIoT success.

We’ve found through working with customers that four to five IIoT use cases should be the maximum starting point, but really should be one to two. Honing in on a few specific use cases is more likely to generate an initial IIoT win and minimize the risk of rework of mistakes. Significant cost factors can add up when over-extending IoT use cases or they do not scale, which can potentially cripple an IIoT project.

It’s critical to get over the initial inertia and resistance that a company will naturally face when adopting any new technology. Implementing an IIoT strategy is no different, and preemptively measuring use cases with the best chance of success and understanding the necessary inputs across products, processes, and people reduces this cultural friction.

There are two market occurrences significantly inhibiting IIoT from scaling: organizations opting to develop a ‘do-it-yourself’ DIY IIoT solution or selecting one-off ‘spot solutions’.

DIY refers to any company opting to build instead of buy IIoT capabilities. However, research shows three out of four DIY IoT projects are reported failures, as companies cannot overcome significant hurdles including costs, time, resources, and scaling.

‘Spot solutions’ are technologies that solve a single use case or problem, typically with only short-term imperatives in purview for a few personnel. This inhibits future scaling as the short-term mend likely isn’t interoperable with other technologies and systems the decision-maker is looking to integrate in the future. These ‘spot’ solutions miss the ‘sweet spot’ of digital transformation that incorporates business, manufacturing, and technology.

The market is starting to resonate that these DIY and spot solution technology adoption methods are not working. Increasingly companies are looking for IIoT platforms that aim for the ’80-20’ rule, meaning 80% is pre-coded and reusable and only 20% of time is needed for customization and integrations. An IIoT platform that is flexible enough to work across a manufacturer’s global diverse factories is far more valuable than one that works well in a few. This common platform requires applications that can immediately solve today’s problems, integrate with existing systems, while providing a scalable framework for customers to take on the long-term digital transformation journey.

Adopters opting for this common platform path are better positioned for growth and to transition IIoT use cases to the market; according to PTC’s State of The Industrial Internet of Things report, 89% of respondents expect to transition use cases to production within a year of purchase.

To achieve this rapid success, partnering with companies with deep expertise on the factory floor and a hands-on experience in circumventing potential problems is a must. We’ve unfortunately seen many organizations incapable of integrating and scaling from previously implemented spot selections and initial ‘IIoT DIY’ers’ spend upwards of six figures before realizing they couldn’t build out the IoT platform they thought they could; don’t be another IIoT failure statistic! While at PTC we can fix your IIoT failure, we’d rather help you succeed from the beginning and be your digital transformation partner for the long-term.

Success will start with navigating the array of IIoT possibilities and identifying the most impactful use cases and solutions to the business. To arrive at this IIoT strategy, the business, manufacturing, & technology framework will expedite the proof-of-value timeline and result in higher rates of success.

Barry Lynch is the Senior Vice President of Field Services at PTC. He has over 25 years of experience in helping manufacturers implement process improvement strategies to attain better performance. At PTC he leads the Factory Services Unit (FSU), partnering with companies to guide them on their digital transformation journey.

Previous to PTC, Lynch spent 10 years with Rockwell Automation and 15 years at GE Digital. Most recently, he was the CEO of Factora , a system integrator focused on implementing Industry 4.0 solutions in manufacturing. Factora was acquired by PTC in 2019.

©Copyright 2026. All rights reserved by Modelcam Technologies Private Limited PUNE.