In the quickly changing industrial landscape of today, enterprises must decide if AI or classical automation in manufacturing produces superior results. Knowing the advantages and disadvantages of each strategy is essential for maintaining competitiveness as companies transition to smarter factories.

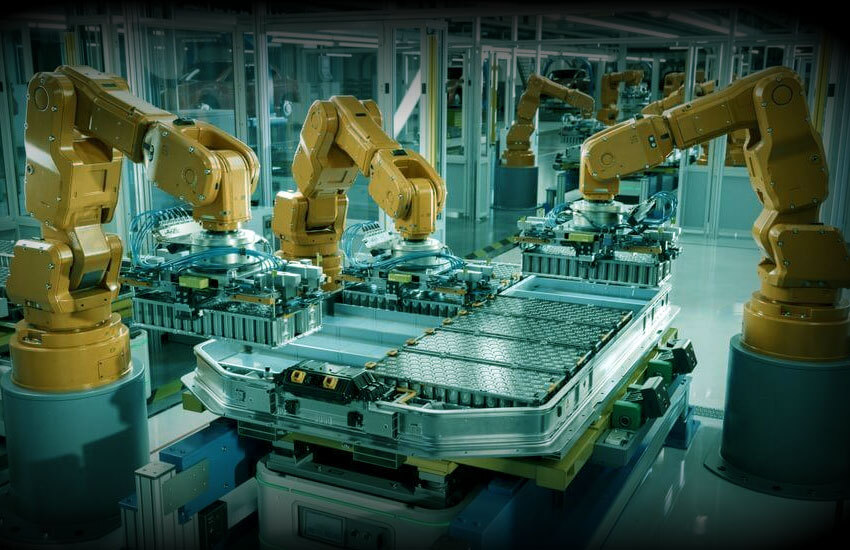

Manufacturing automation has been the foundation of industrial efficiency for many years. Conventional automation reduces human error and increases productivity by carrying out repetitive activities using pre-programmed instructions. These systems, which range from robotic arms to assembly lines, are made to be scalable and consistent.

But conventional automation isn't flexible enough. Any change in process or product design typically demands hardware reconfiguration or software updates, resulting in higher expenses and production delays.

Enter artificial intelligence (AI), a game-changing technology that adds intelligence, adaptability, and predictive power to the manufacturing process.

AI in manufacturing optimizes production processes by utilizing data analysis, machine learning, and AI-driven algorithms. AI systems, as opposed to static automation, don't require manual retraining; instead, they may learn from data, adjust to changing circumstances, and get better over time.

Modelcam Technologies offers cutting-edge AI-based manufacturing solutions that seamlessly incorporate AI into industrial workflows. By fusing automation and AI-driven insights, the company creates manufacturing systems that are more intelligent and flexible.

Get to know more about AI in manufacturing through our blog post, “AI in Manufacturing: Shaping the Future of Smarter Factories”!

Here are some key areas where automation and artificial intelligence differ:

| Feature | Traditional Automation | AI in Manufacturing |

|---|---|---|

| Flexibility | Low – Rule-based and rigid | High – Learns and adapts in real-time |

| Scalability | High for repetitive tasks | High for dynamic environments |

| Data Utilization | Minimal data feedback | Extensive data analysis and insights |

| Maintenance | Reactive or scheduled | Predictive maintenance with AI |

| Decision-Making | Pre-programmed only | AI-driven decisions based on analytics |

| Cost-Efficiency Over Time | Moderate | High (due to optimization and fewer downtimes) |

AI in industrial automation offers agility, predictive capabilities, and real-time optimization, whereas classical automation is best suited for repetitive, high-volume activities.

The advantages of AI in manufacturing extends well beyond automating repetitive tasks.

Predictive analytics: AI lowers maintenance expenses and downtime by anticipating equipment breakdowns before they occur.

Smart Manufacturing with AI: Real-time data processing maximizes output while lowering waste and raising quality.

AI-Powered Smart Factories: By incorporating AI, factories become intelligent ecosystems with the ability to self-correct and self-monitor.

AI Applications in Manufacturing: AI improves every stage of the process, from supply chain optimization to quality control.

By incorporating AI in production processes, manufacturers obtain a competitive edge through agility, efficiency, and lower operational risks.

Even while traditional automation in industry has proven dependable for many years, it is insufficient in the rapidly evolving markets of today:

Lack of Flexibility: Changes in the product design result in production line interruptions because of poor adaptability.

High Maintenance Costs: Manual inspections are necessary for rigid systems on a regular basis.

Limited Data Insights: Although automation systems gather data, they are unable to perform analysis.

On the other hand, real-time data analysis and predictive analytics made possible by AI integration in manufacturing systems enable continual development.

Automation is being redefined by the combination of AI and robotics in factories. AI-powered robots are able to work with humans, do sophisticated, non-repetitive jobs, and make snap decisions. Industry 4.0 and AI advancements, where machines interact, evaluate, and optimize together, are made possible by this synergy.

AI-enabled robotics at Modelcam Technologies increase total equipment effectiveness, decrease mistakes, and increase production flexibility.

AI in business affects consumer experience beyond manufacturing. Manufacturers can improve customer retention, anticipate consumer demands, and personalize services by utilizing customer data analysis. Voice search optimization enhances product discoverability in digital channels, and AI-driven behavioral targeting makes marketing techniques more successful.

With AI-driven solutions, manufacturers can create customized, data-supported interactions that boost customer retention.

AI-powered manufacturing offers intelligent supply chains, self-governing processes, and real-time optimization at every stage. Manufacturers will depend more on AI applications in manufacturing to boost innovation and efficiency as AI-powered smart factories develop.

Machine learning in manufacturing makes it possible for systems to learn and get better over time, resulting in a self-optimizing environment. This development signifies a change from reactive to proactive operations and is consistent with Industry 4.0 and AI.

Industry 4.0 and AI are inextricably connected. Industry 4.0 is based on connectivity, intelligence, and real-time data processing - all of which are powered by artificial intelligence (AI), whereas earlier industrial revolutions relied heavily on traditional automation.

Manufacturers are now heading towards a future where machines can self-diagnose problems because of AI integration in manufacturing systems.

Depending on demand, production lines automatically reorganize.

Machines self-diagnose issues.

Continuous improvement is made possible by this change, which also improves product quality and client retention.

So, AI vs traditional automation in manufacturing - what’s better? Depending on your objectives:

Conventional automation is still economical for repeated, routine work.

AI-based manufacturing solutions provide unmatched benefits for processes that are dynamic, complex, and data-driven.

In many cases, the best solution involves a blend of different strategies. By adding intelligence to traditional automation, the integration of AI in industrial automation allows producers to continuously adapt, forecast, and optimize.

Strategic planning is necessary when switching from automation to AI integration in manufacturing systems:

Determine pain points and evaluate the present automation levels.

Use AI-powered solutions to improve capabilities and solve inefficiencies.

To facilitate predictive analytics and real-time data analysis, make an investment in data infrastructure.

Train workforce to work together with AI-enabled systems.

Experts at Modelcam Technologies help manufacturers implement AI-based manufacturing solutions that are customized for their unique requirements, guaranteeing a smooth transition to more intelligent production.

AI in manufacturing is a paradigm change rather than merely an improvement in the rapidly changing field of manufacturing. Automation sets the groundwork, but AI-powered solutions are constructing the future with their intelligence, flexibility, and capacity for prediction.

Businesses may achieve new levels of efficiency and innovation by integrating AI applications in manufacturing, embracing predictive maintenance with AI, and combining AI and robotics in factories. The secret to prospering in the era of Industry 4.0 and AI is the path towards AI-powered smart factories.

"AI vs. automation" is no longer the only question at hand. It's about combining the two to build a robust, forward-thinking industrial ecosystem.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.