Another name for Additive manufacturing (AM) is 3D printing. Additive manufacturing (AM) is a technology that is rapidly evolving. This technology has the potential to transform or restructure the way products are manufactured. Additive manufacturing technologies offer a number of advantages over traditional manufacturing methods, such as the ability to create complex geometries, produce parts with less waste, and shorten production lead times.

Modelcam Technologies is a premium provider of CAD/ CAM/ CAE solutions. It provides the best engineering design services in India.

Conventional manufacturing, on the other hand, is a broad term that encompasses a variety of traditional manufacturing processes, such as machining, casting, and forging. These processes have been used for centuries to produce a wide range of products.

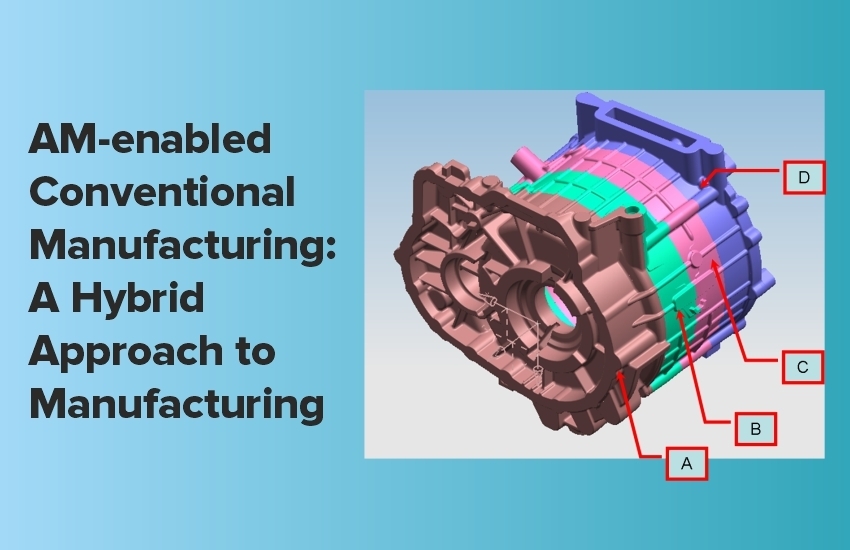

AM-enabled conventional manufacturing is a combination of both. It is a technology that combines both manufacturing ways. It uses Additive manufacturing (AM) to create the initial prototype or tooling and then uses conventional manufacturing to produce the final product.

Reduced development time and cost: AM can be used to quickly and easily create prototypes, which can help to identify and correct design flaws early in the development process. This has the ability to save time and money in the long run.

Increased design freedom: AM allows for the creation of complex geometries that would be difficult or impossible to produce using traditional manufacturing methods. This can help to create new product designs that are innovative too.

Improved performance: AM can be used to create parts with superior properties, such as strength, stiffness, and weight savings. This can lead to improved performance of the final product.

Increased flexibility: AM can be used to produce small batches of parts or even one-off parts. This can be useful for applications where there is a high degree of product customization or where the demand for the product is unpredictable.

Reduced material waste: AM only uses the material that is needed to create the part, which can lead to significant savings in material costs.

Improved energy efficiency: AM can be a more energy-efficient manufacturing process than traditional methods, such as machining.

Reduced environmental impact: AM can help to reduce the environmental impact of manufacturing by reducing material waste and energy consumption.

Overall, AM-enabled conventional manufacturing offers a number of advantages over traditional manufacturing methods. It can help to improve product design, performance, and flexibility, while also reducing costs and environmental impact.

Like benefits, AM-enabled conventional manufacturing also has some drawbacks.

High initial investment: The cost of AM machines can be high, which can make it a barrier to entry for some businesses.

Limited materials: AM is not yet capable of using all materials, so it may not be suitable for all applications.

Post-processing: AM parts often require post-processing, such as machining or heat treatment, which can add to the cost and time of production.

Quality control: AM can be a complex process, and it can be difficult to ensure consistent quality of the parts produced.

Lack of standards: There are still no universally accepted standards for AM, which can make it difficult to exchange information and data between different machines and software.

Though AM-enabled conventional manufacturing offers a number of advantages over traditional manufacturing methods, there are also some challenges that need to be addressed before it can become more widely adopted. As AM technology continues to mature, it is expected that these challenges will be overcome and AM-enabled conventional manufacturing will become a more common manufacturing practice.

AM-enabled conventional manufacturing is still a relatively new technology, but it is gaining traction in a number of industries. Some of the industries that are currently using AM-enabled conventional manufacturing include:

Aerospace: AM is being used to produce lightweight, high-performance parts for aircraft and spacecraft. For example, GE Aviation is using AM to produce fuel-efficient fuel nozzles for jet engines.

Medical: AM is being used to produce custom implants, surgical tools, and other medical devices. For example, Stryker is using AM to produce custom knee implants that are tailored to the individual patient's anatomy.

Automotive: AM is being used to produce prototypes, tooling, and even finished parts for cars and trucks. For example, BMW is using AM to produce lightweight, high-performance pistons for its engines.

Consumer goods: AM is being used to produce a variety of consumer goods, such as jewelry, eyewear, and sporting goods. For example, Nike is using AM to produce custom-fit insoles for its shoes.

As AM technology continues to mature, it is expected that AM-enabled conventional manufacturing will become even more widespread. This is because AM offers a number of advantages that can help manufacturers improve their products, reduce their costs, and increase their flexibility.

In the aerospace industry, AM is being used to produce fuel-efficient aircraft components, such as wing spars and turbine blades. AM is also being used to produce complex tooling for the assembly of aircraft components. For example, Airbus is using AM to produce tooling for the assembly of its A350 aircraft.

In the medical industry, AM is being used to produce custom implants, such as hip replacements and dental crowns. AM is also being used to produce surgical tools, such as drill bits and saws. For example, Medtronic is using AM to produce custom spinal implants.

In the automotive industry, AM is being used to produce prototypes, tooling, and even finished parts for cars and trucks. AM is also being used to produce lightweight, high-performance components, such as pistons and connecting rods. For example, Ford is using AM to produce lightweight, high-performance exhaust manifolds for its EcoBoost engines.

In the consumer goods industry, AM is being used to produce a variety of consumer goods, such as jewelry, eyewear, and sporting goods. AM is also being used to produce customized products, such as custom-fit hearing aids and prosthetic limbs. For example, Ray-Ban is using AM to produce custom sunglasses frames.

AM-enabled conventional manufacturing is a powerful combination that has the potential to revolutionize the way products are manufactured.

As AM technology continues to mature, it is expected that AM-enabled conventional manufacturing will become even more widespread.

Modelcam Technologies provides various 3D Design and engineering services. It provides engineering design services in USA along with engineering design services in India.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167 / 020-29994105 , 29996327.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.