Engineering and manufacturing processes are changing significantly in the ever changing digital world of today. Traditional simulation and digital twin are two important technologies influencing this development. Although they both seek to increase product development's efficiency, performance, and dependability, their primary features and applications differ greatly. We will examine real-world digital twin applications in manufacturing, examine the dispute between digital twin vs simulation, and show how companies may use AI-driven solutions to get better results.

Conventional simulation uses computing tools and mathematical models to forecast how systems will behave in different scenarios. Engineers can better understand design performance, stress factors, and predicted behavior under particular settings by using these simulations, which are frequently done prior to product construction.

In model-based systems engineering, classical simulation is essential, but it has drawbacks. Usually, it is a static procedure that does not include real-time data from working surroundings, instead depending on predefined input parameters. Stated differently, the simulation cannot dynamically adapt to real-world performance once it is finished.

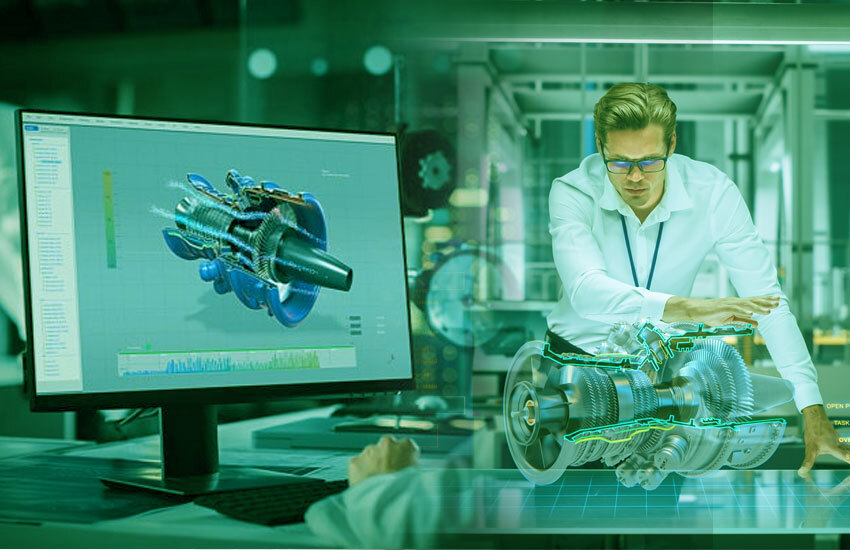

A digital twin is a digitally connected version of a physical system, driven by real-time data for accurate simulation and monitoring.

Digital twin are constantly updated with IoT sensor data, AI-powered analytics, and past performance insights, in contrast to traditional simulation.

What is digital twin technology precisely then? Fundamentally, it creates a living model that changes during a product's lifecycle by fusing AI, data automation, and sensor integration. Traditional simulations are unable to replicate the predictive maintenance, design enhancements, and operational efficiency made possible by the real-time digital twin.

For more information about digital twin, explore our blog post, “What is Digital Twin Technology? Applications and Benefits Explained”!

Let's take a closer look at the simulation vs digital twin comparison:

| Feature | Traditional Simulation | Digital Twin |

|---|---|---|

| Data Input | Predefined & static | Real-time & dynamic |

| Interaction | One-time analysis | Continuous feedback loop |

| Usage | Design validation | Full lifecycle management |

| AI Integration | Minimal | High (includes AI-driven insights) |

| Decision Making | Manual | Automated and predictive (with Predictive Analytics) |

| Scope | Individual components | Complete systems and processes |

This contrast makes it abundantly evident why digital twin are transforming how companies approach product management, monitoring, and design.

One of the most revolutionary developments of Industry 4.0 is the use of digital twin in manufacturing. Digital twin are used by manufacturers to increase productivity, decrease downtime, and improve quality in anything from process optimization to predictive maintenance of machinery.

Our specialty at Modelcam Technologies is combining CAD and simulation tools with digital twin software to assist manufacturers in visualizing and streamlining each phase of the product lifecycle. Our products give businesses looking to improve customer satisfaction, cut expenses, and maintain their competitiveness access to the potential of industrial digital twin systems.

Use cases for digital twin in the real world:

Production Line Monitoring: By simulating the assembly line, a digital twin can spot performance snags using real-time data and recommend fixes using AI-powered models.

Product Customization: To provide specialized product features, the twin model is fed client preferences obtained through consumer data research.

Predictive Maintenance: By employing predictive analytics to anticipate equipment breakdown, the system minimizes unscheduled downtime.

These digital twin use cases demonstrate how integrating IoT, AI, and data modeling produces significant real-world results.

When comparing digital twin vs simulation, the advantages of digital twin are instantly noticeable:

Digital twin offer continuous, real-time insights that facilitate quicker decision-making than traditional simulations, which are snapshots in time.

The virtual model can better represent operating situations by utilizing real-time digital twin data from sensors, artificial intelligence, and edge devices.

Digital twin, supported by AI-powered sales forecasting and sales automation tools, can predict results before they occur, increasing return on investment and cutting waste.

By using the twin to understand product usage patterns, behavioral targeting and improved customer retention tactics can be implemented.

IoT and digital twin platforms work together to provide real-time alerts, continuous learning, and system adaptability, which gives you an advantage over static simulation.

The use of digital twin technology is greatly improving the way that goods are created and evaluated. Engineers can iterate more effectively by leveraging live data to virtually prototype the design. Early defect detection, lower prototyping costs, and a quicker time to market are all made possible by the digital twin in product design.

Furthermore, by recommending the best design changes based on historical performance data and customer behavior analysis, generative AI and AI in business intelligence enhance these iterations even more.

Distinguishing between digital thread vs digital twin is key to unlocking their full potential. A digital thread is the data flow and connectivity across the product lifecycle, from design to deployment, whereas a digital twin is a real-time virtual equivalent.

Model-based systems engineering can function more intelligently when digital twin and digital threads are combined, guaranteeing total traceability and uniformity throughout teams.

Deeper integration with AI-driven solutions, CRM AI, and sophisticated data analysis tools is key to the future of digital twin technology. Industries are heading toward digital twin ecosystems that use machine learning algorithms to act autonomously in addition to simulating and monitoring.

Digital twin are anticipated to spur innovation in the following areas in the years to come:

Automotive and aerospace

Infrastructure and smart cities

Medical devices and healthcare

Utility and energy

In order to assist organizations fully utilize the digital twin benefits for more intelligent operations and improved performance, we at Modelcam Technologies are constantly updating our digital solutions to reflect this future.

The digital twin vs. simulation contrast makes it abundantly evident that digital twin provides a more comprehensive, intelligent, and real-time approach, even though traditional simulation has a role in design and analysis. Digital twin in manufacturing and design are quickly emerging as a key component of digital transformation thanks to features like real-time data integration, AI-driven predictive analytics, and seamless IoT connectivity.

Speak with the professionals at Modelcam Technologies if you are prepared to discover the benefits of digital twin software and investigate cutting-edge digital twin use cases for your company. Allow us to assist you as you confidently enter the smart industrial future.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.