Today, we are witnessing the rise of Fourth Industrial Revolution, (which is also popular as Industry 4.0) and Internet of Things, IoT, is being said to be the driving force of this revolution. If we look closely, the Internet of Things, IoT, has begun to influence the manufacturing industry in a positive light - mostly. It is reasonably transforming the workflow & management processes… and is creating smart factories out of the manufacturing sector.

IoT is said to be a closed network of all the objects that breathe-digits and codes and are allowed to communicate with each other in terms of sharing data, over the internet without human intervention. Further, when the concept of IoT is applied to the large scale industries such as Manufacturing –IoT becomes IIoT which is; Industrial Internet of Things.

Industrial Internet of Things- uses embedded sensors, cloud-based data, and interconnected smart devices on the manufacturing floor to derive artificial intelligence, predictive analytics and to ensure better industrial performance.

Looking at the opportunities piled up by the new age technologies such as - AI and machine learning, Big Data, Robotics & specifically by Internet of Things (IoT) -- many enterprises have taken a leap in transforming their processes into automation. The industrial branch based on intelligent automation and empowered by smart digital solutions with the aim to optimize production is called SMART MANUFACTURING.

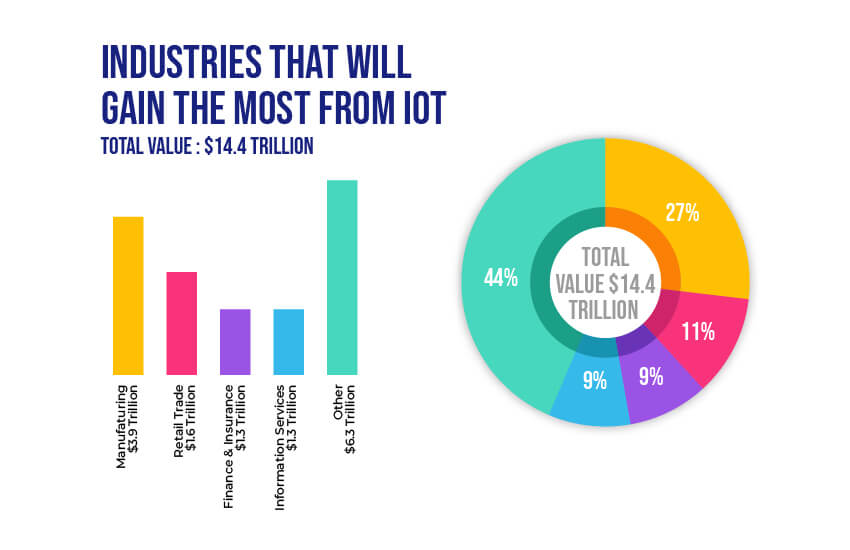

Manufacturing is the sector most affected by IIoT, with a potential economic impact of $3.9 trillion to $11.1 trillion a year by 2025.

The German industrial IoT market will see rapid growth by 2025 in terms of three components: solution, service and platform. A survey conducted in Germany by PwC reveals the following findings:

The Fourth Industrial Revolution, also known as Industry 4.0, has brought forth profound changes across various industries, with the Internet of Things (IoT) being one of the primary driving forces. IoT is significantly impacting the manufacturing industry by transforming traditional workflows into efficient, automated systems. When applied to industrial settings, IoT evolves into the Industrial Internet of Things (IIoT), integrating smart devices, sensors, and cloud computing to optimize manufacturing processes and improve overall productivity.

The most of the manufacturers have already set their path in transforming their businesses because they see the following advantages of implementing industrial IoT in smart manufacturing:

IIoT uses interconnected devices and sensors embedded in machinery and systems on the shop floor. These devices gather data, which is then sent to cloud-based platforms where advanced technologies like Artificial Intelligence (AI), machine learning, and predictive analytics are employed to interpret and act on this information. This enables real-time monitoring of machines, equipment health, and production lines, leading to predictive maintenance, automated decision-making, and efficiency optimization.

The integration of IIoT not only enhances the performance of manufacturing systems but also facilitates the creation of smart factories. These smart factories use data-driven insights to streamline operations, reduce waste, improve product quality, and ensure flexibility in production lines. By collecting data from every aspect of the production process, manufacturers can make more informed decisions, optimize resources, and improve operational performance.

IoT is revolutionizing manufacturing as it accelerates productivity, increases efficiency, minimizes downtime and provides a competitive edge for businesses. MODELCAM is a reliable partner and is best known to provide online IoT courses at lucrative prices. For details, let's get connected at- MODELCAM

©Copyright 2026. All rights reserved by Modelcam Technologies Private Limited PUNE.