Industrial enterprises are under increasing pressure to provide competitive differentiation and improve customer satisfaction. This pressure doesn’t subside after products and equipment come off the line. Product performance and uptime are key factors that can help manufacturers win market share, making aftermarket field service a critical component in industries like high-tech, automotive, industrial products, federal aerospace and defense, and life science.

Field service provides manufacturers with additional opportunities to deliver revenue and profit streams, but several considerations make profitability difficult to attain:

- Increasingly complex products and configurations require complex service information

- Reliable, multi-language service information is needed to support a global marketplace

- Traditional printed manuals are ineffective and costly to maintain and distribute

- Field service operations can be expensive, particularly for equipment located in remote areas

- Expert field service technicians are retiring and not adequately being replaced

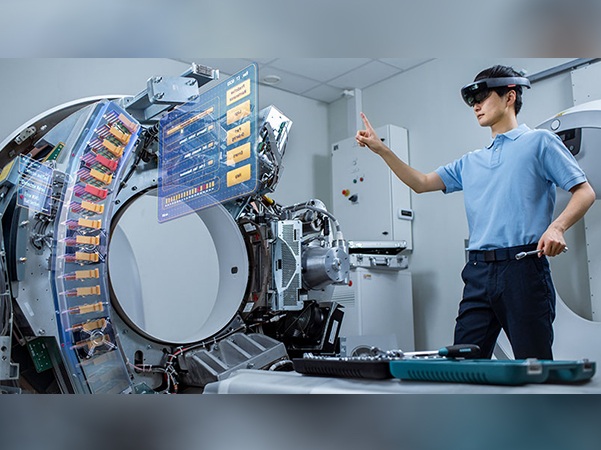

A successful field service model requires a combination of accurate service information and an able workforce. Service providers around the world are overcoming these common challenges by using augmented reality (AR) to deliver relevant service information and guidance that technicians need – when and where they need it.

AR allows service technicians to quickly perform processes, repairs, and the disassembly and reassembly of parts without the physical interruption of pausing to refer to separate printed manuals. Instead of printing and distributing difficult-to-interpret service manuals, service providers can leverage mobile devices and hands-free headsets to deliver 3D work instructions that boost technician productivity. Overlaying real-time, up-to-date information onto physical equipment allows technicians to visualize previously inaccessible things, like machine data or components inside a product, before they perform a task. It also guides them through processes while they are performing tasks.

In the event that field technicians come across unfamiliar or unexpected equipment problems that require additional guidance or support, they can use AR to immediately connect with a remote expert that can help them. This ability to solve problems collaboratively and in real-time makes it easier for service organizations to scale their expertise and optimize high-value resources.

Service organizations can also use AR to train technicians up to 50% faster. Organizations that have utilized AR-powered training experiences were able to accelerate ramp up times and employee learning curves by engaging relevant learning and memory systems in the brain. And because AR is such an effective knowledge sharing tool, service providers can minimize off-site training and other costly training activities with impactful on-the-job training.

Ineffective service manuals can have a ripple effect on field service performance and customer satisfaction. Inaccurate or difficult-to-understand information compromises technician efficiency, resulting in slow resolution times, repeat visits, high equipment downtime, high part returns, handling costs and excess parts inventory, repair and maintenance delays, and ultimately, frustrated customers.

AR enables service providers to deliver and maintain accurate service and parts information that field technicians need to be productive. AR authoring solutions allow expert technicians to quickly create scalable service work instructions that are easy for any technician to understand and follow. AR’s of use visual icons and physical reference points help service providers minimize translation costs and development time. The ability to view 3D service instructions on a hands-free headset or mobile device enables service technicians to access critical and supplemental information in the context of the actual task they’re performing, which helps to improve repair times and first-time fix rates.

Augmented reality is providing industrial enterprises with millions in benefits and savings. For a detailed breakdown of the value that AR can bring to your business, download The Total Economic Impact™ Of PTC Vuforia, a July 2019 commissioned study conducted by Forrester Consulting.

Greg is an avid blogger interested in industrial innovation, technology, and the intersection between the two. As a Content Marketing Specialist for PTC, Greg is excited about how things like virtual and augmented reality, the internet of things, and predictive analytics are shaping the future of manufacturing.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.