Engineers need strong, user-friendly, and adaptable tools to make ideas a reality in the fast-paced world of product design and innovation. PTC Creo Parametric is a well-known brand in this field and is a top choice for experts looking for state-of-the-art design skills. For almost two decades, Modelcam Technologies has led the CAD software industry. By providing strong support and solutions for PTC Creo engineering software, the company continues to empower engineering teams across industries.

Creo Parametric Software provides the performance and scalability needed for contemporary product development, whether you're making intricate components, sizable assemblies, or sophisticated digital prototypes.

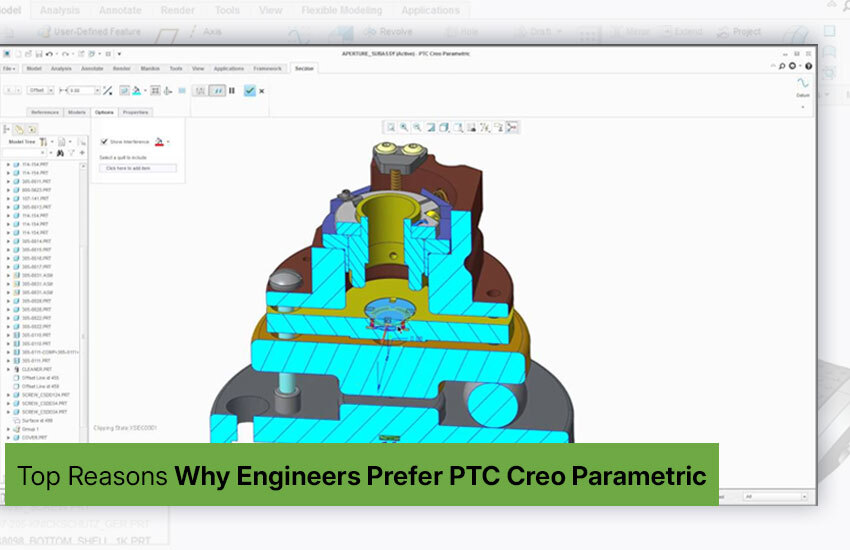

Creo Parametric's robust suite of parametric modeling tools, which provide engineers complete control over design intent, is its core feature. Designers can establish relationships between features using parametric modeling, which makes it possible for any changes to be immediately reflected throughout the model.

It is the best CAD software for engineers working on intricate, dynamic projects because of its features, which improve design accuracy, encourage consistency, and drastically cut down on iteration time. Clients always work with the best configurations catered to their industry demands thanks to Modelcam's proficiency in implementing parametric CAD software solutions.

Superior geometry handling and performance with large assemblies are hallmarks of Creo Parametric 3D modeling. Engineers that deal with intricate mechanical systems value its accuracy, speed, and adaptability.

Among the main characteristics are:

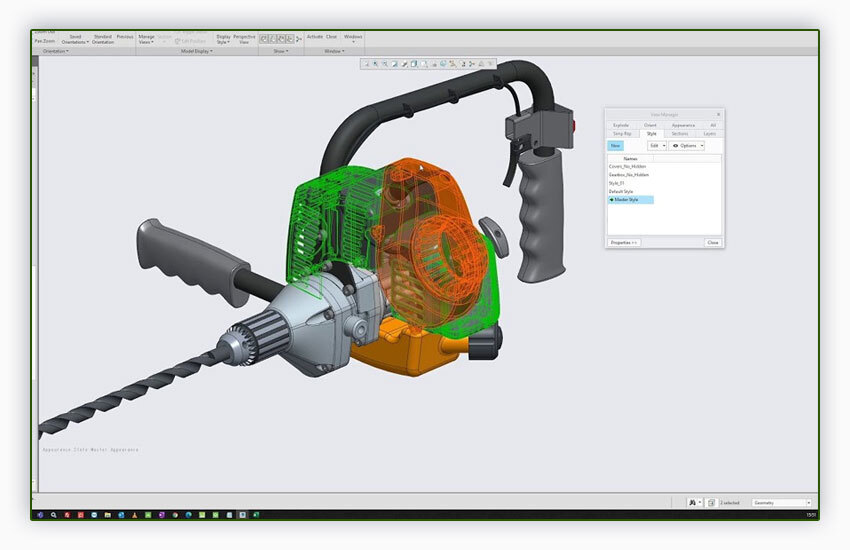

Real-time shading and visualization

A user-friendly interface for modeling surfaces and solids

Associative drafting in both two and three dimensions

For comparison between Creo and Solidworks you can refer to our blog, “Creo 11 vs SolidWorks: Which CAD Software is Right for You?”!

In order to minimize errors and prototyping expenses, design validation is essential. Stress testing, motion studies, and heat analysis are all made possible by simulation in Creo - all within the same interface.

Modelcam's installation services allow businesses to benefit from intelligent validation workflows by seamlessly integrating simulation into Creo.

The way engineers handle product documentation is changing as a result of model-based definition (MBD). MBD does not require traditional 2D drawings since it integrates all product manufacturing information (PMI) directly into the 3D model.

Design automation with Creo helps engineers expedite repetitive tasks and minimize manual errors in the face of mounting time and budget constraints.

Reputable PTC Creo Parametric solution provider Modelcam Technologies helps companies use automation to increase design productivity and save development cycles.

Before physical manufacturing, engineers can design, test, and improve virtual models using Creo's digital prototyping tools.

This feature facilitates:

Product development that is economical

Improved client satisfaction

Greater retention rates as a result of quicker delivery

Creo Parametric software's capacity to grow with your company, from concept design to production and beyond, is one of its most alluring features.

With the aid of generative design tools, engineers can automatically investigate thousands of design possibilities while adhering to limitations such as cost, weight, and strength.

Modelcam Technologies has been offering engineering solutions for over 23 years. It offers:

Thorough CAD instruction and assistance

Automation-related services

CAD customization for particular sectors

Engineers working in the field of modern product development require tools that are reliable, clever, and prepared for the future. With its precise modeling, design automation, simulation, and integration features, PTC Creo Parametric is the best option.

Businesses may fully utilize Creo Parametric 3D modeling when it is deployed with knowledgeable assistance from Modelcam Technologies, which turns concepts into creative, quickly and precisely manufactured goods.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no: +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.