Engineers in today's cutthroat manufacturing environment want more than simply strong design tools; they want flexible and intelligent solutions that can change with the needs of the project. For this reason, BricsCAD Mechanical is becoming more and more popular among design experts. It provides a smooth fusion of conventional drafting and contemporary 3D modeling power, and is well-known for its strong capabilities and well-known DWG-based platform.

This 3D mechanical CAD software enables engineers to produce manufacturing-ready CAD models more quickly and accurately, regardless of whether they are creating elaborate assemblies, complex equipment, or sheet metal enclosures. Let's examine the reasons behind BricsCAD Mechanical's rise to prominence as the preferred option for flexible mechanical CAD design.

BricsCAD Mechanical's parametric modeling capacity is one of its best qualities. Engineers can create models using this method that react intelligently to modifications in the design. When dimensions change, parameters and constraints automatically update related features rather than requiring manual redrawing of certain areas.

As a result, design teams will collaborate more effectively, make iterations more quickly, and make fewer mistakes. It is particularly helpful in businesses that move quickly and where product specifications change often. Higher design flexibility while preserving design intent can be attained by engineers by including parametrization & constraints into routine procedures.

BricsCAD Mechanical's powerful sheet metal design tools are another noteworthy feature. With just one click, engineers can quickly design sheet metal components, apply bends, joints, and reliefs, and then unfold them for manufacturing. By ensuring precise flat designs that meet manufacturing standards, the program lowers scrap and rework.

This optimized sheet metal workflow speeds up design-to-production cycles for metal fabrication businesses. Additionally, it works well with standard libraries (hole features, form features), which guarantees uniformity in designs and expedites the detailed stage.

BricsCAD Mechanical utilizes DWG-based drafting, which ensures complete compatibility with existing design archives, in contrast to many other CAD products that depend on proprietary formats. Legacy drawings can be easily incorporated into new projects by engineers.

Teams may work with suppliers and clients using different CAD systems without experiencing format issues because of the DWG foundation's support for multi-CAD data reuse and interoperability. Engineers may expedite project schedules and concentrate more on innovation than file transformations by bridging data silos.

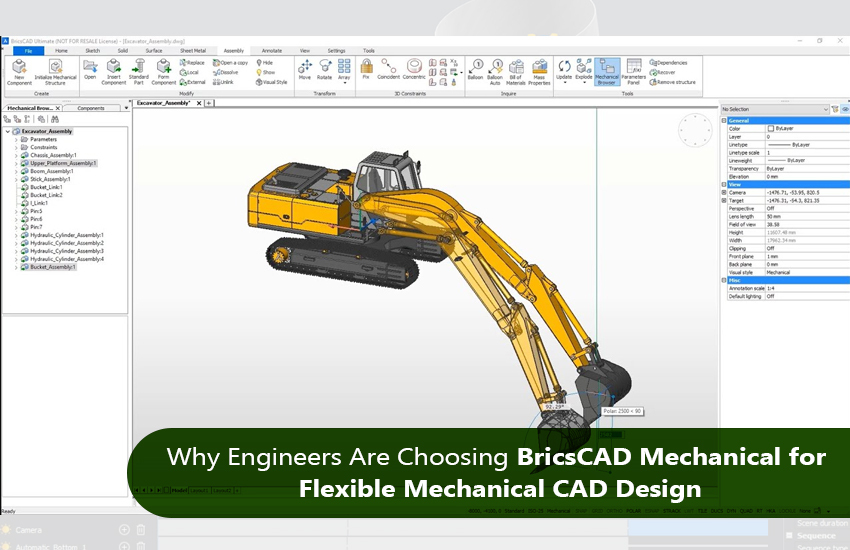

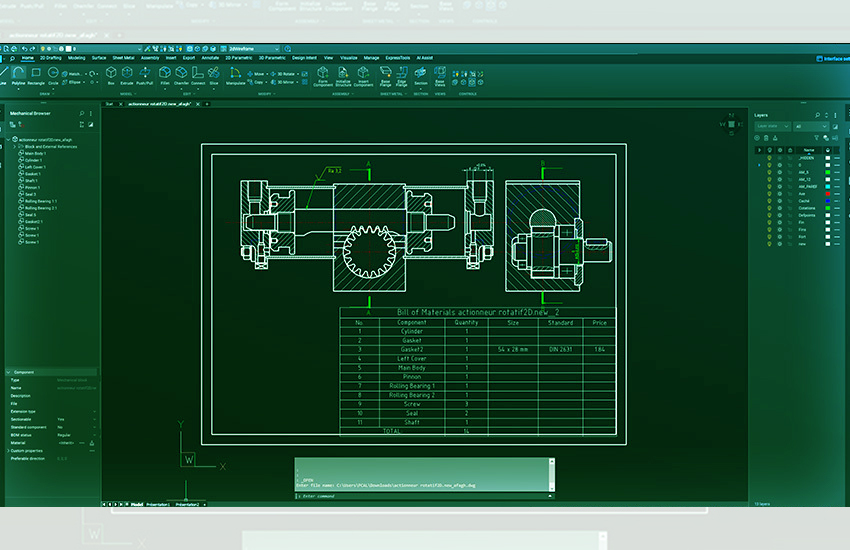

Hundreds or even thousands of components must be precisely coordinated in complex machinery systems. To tackle this complexity, BricsCAD Mechanical offers robust assembly design and BOM management tools. Engineers are able to handle relationships, create Bills of Materials automatically, and organize assemblies in a hierarchical fashion.

Manufacturers can expedite procurement and maintain precise part counts with the aid of these solutions. The program guarantees that designs remain structured and production-ready from conception to manufacture when used in conjunction with its mechanical parts & components design capabilities.

Engineers frequently need to make last-minute modifications to geometry, even though parametric design is excellent at planned alterations. Direct modeling is a feature of BricsCAD Mechanical that allows you to easily push, pull, or change 3D geometry without compromising design intent.

Furthermore, variational 3D modeling allows users to make design changes dynamically while preserving important geometric relationships by combining the best features of direct and parametric modeling. Engineers may be as flexible as possible when developing concepts and making last-minute design changes with this hybrid technique.

Efficient documentation tools are essential to a robust CAD platform. With automatic drawing views, section views, and detail views produced straight from 3D models, BricsCAD Mechanical simplifies the process of creating 2D drawings.

By ensuring that drawings are constantly current with the most recent model modifications, these technologies help to minimize production errors. When coupled with fast 2D detailing capabilities, engineers can create precise, lucid documentation faster, which is crucial for projects with tight deadlines.

Today's engineering teams seek cognitive insights that boost business productivity, not just design capabilities from CAD software. BricsCAD Mechanical facilitates this change by making it possible to incorporate AI into corporate processes.

Design data can be connected to business systems for customer data analysis, sales automation tools, or customer relationship management (CRM) AI through the use of AI-driven solutions and data automation. This enables businesses to monitor consumer preferences, make data-driven design choices, and react to market demands faster. Businesses can improve their product development and sales by connecting CAD design to more comprehensive business analytics.

The speed at which a CAD platform can bring concepts from conception to production is ultimately what makes it valuable. Delivering manufacturing-ready CAD models that meet industry requirements and reduce rework is where BricsCAD Mechanical excels.

The manufacturing process is further accelerated by its native compatibility with CAM and PLM platforms. The seamless translation of their concepts into production will save delay and expensive mistakes on the factory floor, giving engineers peace of mind.

For contemporary engineering teams, BricsCAD Mechanical is proving to be a wise investment in a world where accuracy, speed, and flexibility are essential. It provides an all-in-one platform to create creative products more quickly by fusing the capability of 3D mechanical CAD software with user-friendly tools for parametric modeling, direct modeling, sheet metal design tools, and assembly design & BOM management.

Engineers may collaborate easily on both new and legacy projects thanks to its support for parametrization & constraints, DWG-based drafting, and multi-CAD data reuse and interoperability. Its ability to integrate with AI-driven solutions and customer data analysis systems, however, makes it a progressive option for businesses looking to combine business intelligence and design.

Want to know why BricsCAD Mechanical is engineers’ favorite design tool? Check our informative blog, “Why Choose BricsCAD Mechanical for Your Design Projects?”!

Your product development cycle may succeed or fail based on your choice of CAD platform. BricsCAD Mechanical's extensive feature set, compatibility, and adaptability enable engineers to create without limitations. It covers every facet of the design-to-production pipeline, including standard libraries (hole features, form features), drawing views, section views, and detail views.

It's time to think about BricsCAD Mechanical if your team wants to improve design agility, update workflows, and produce manufacturing-ready CAD models. By collaborating with professionals like Modelcam Technologies, you can efficiently deploy this potent platform and achieve unprecedented engineering efficiency.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.