In today's competitive business landscape, organizations face increasing pressure to innovate rapidly, deliver high-quality products, and meet customer demands efficiently. Product Lifecycle Management (PLM) emerges as a strategic approach to address these challenges, offering a comprehensive framework for managing the entire lifecycle of a product, from inception to disposal. In this blog, we'll explore the core concepts of PLM, its key components, benefits, and how it can revolutionize product development processes across industries.

PLM is a strategic business approach that manages all the information, processes, and people involved in a product's lifecycle. It acts as a central hub, integrating various aspects like design, engineering, manufacturing, service, and disposal. Imagine it as the nervous system of your product, ensuring smooth communication and collaboration throughout its entire lifespan.

Product Lifecycle Management (PLM) encompasses a set of practices, processes, and technologies aimed at managing the complete lifecycle of a product. It involves the coordination and integration of various functions, including product design, engineering, manufacturing, supply chain management, and service. At its core, PLM serves as a centralized platform for capturing, managing, and sharing product-related data and information throughout its lifecycle.

| Component | Description |

|---|---|

| Product Data Management (PDM) | Centralized storage and management of product-related data, including design files, BOMs, and specifications. |

| Collaboration Tools | Facilitates communication and collaboration among cross-functional teams, suppliers, and partners. |

| Workflow Management | Manages processes, approvals, and change management workflows to ensure smooth execution of tasks. |

| Design and Engineering Tools | Includes CAD, simulation, and virtual prototyping tools for product design and validation. |

| Manufacturing Tools | Optimizes manufacturing processes, production scheduling, and quality control. |

| Supply Chain Management (SCM) | Integrates with supply chain processes to manage suppliers, procurement, and logistics. |

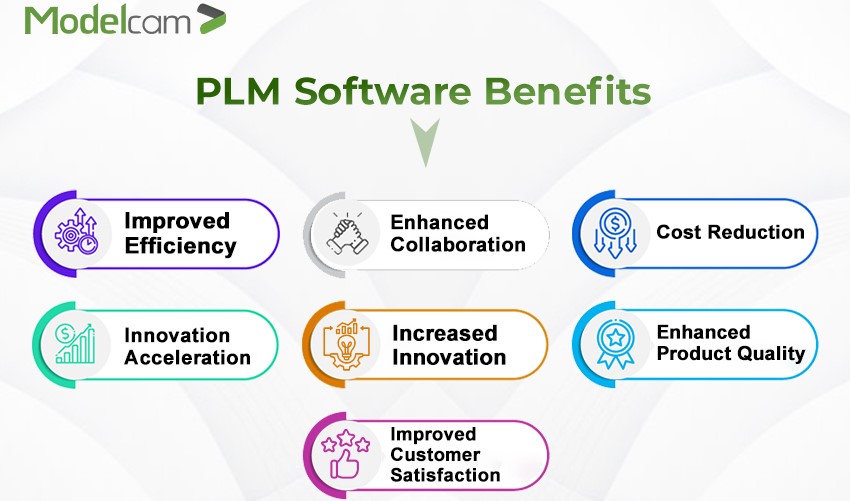

Streamlines processes, reduces time-to-market, and minimizes errors through automation and standardized workflows.

Facilitates seamless communication, document sharing, and version control among dispersed teams.

Optimizes resource utilization, minimizes rework, and enhances decision-making leading to cost savings.

Explore our blog on “5 Ways PLM Can Save Your Company Millions” to know more about how PLM services can become your partner in saving money!

Captures, manages, and leverages intellectual property (IP) to foster innovation and competitive differentiation.

Centralized data and improved collaboration foster innovation by enabling teams to leverage past knowledge and identify opportunities for improvement.

PLM facilitates better control over product quality by ensuring traceability of materials, processes, and documentation.

By optimizing the entire product lifecycle, PLM ultimately contributes to the delivery of higher quality products that meet customer needs.

Challenges faced during CAD customization can be solved using PLM. Read how this can be done in our blog, “7 Common Challenges Solved by Implementing PLM Solutions”!

| Strategy | Description |

|---|---|

| Assessment and Planning | Evaluate current processes, identify objectives, and define success criteria for PLM implementation. |

| Vendor Selection | Research and select PLM software vendors based on functionality, scalability, and compatibility with business needs. |

| Customization and Configuration | Tailor PLM system to align with organizational workflows, data structures, and business rules. |

| Training and Change Management | Provide comprehensive training and support to users, implementing change management strategies to promote adoption. |

| Continuous Improvement | Monitor usage, gather feedback, and iterate on processes to continuously improve efficiency and effectiveness. |

| Before PLM | 18 Months |

| After PLM | 14 Months |

| Development Costs | 10-20% Reduction |

| Manufacturing Costs | 5-15% Reduction |

| Warranty Costs | 5-10% Reduction |

Company XYZ, a leading manufacturer of consumer electronics, faced challenges in managing its product development processes across dispersed teams and global supply chain partners. By implementing PLM, Company XYZ transformed its product lifecycle management practices, achieving significant improvements in efficiency, collaboration, and innovation. Through centralized data management, streamlined workflows, and enhanced communication, Company XYZ reduced time-to-market, optimized resource utilization, and increased product quality. PLM enabled Company XYZ to maintain its competitive edge in the fast-paced consumer electronics market while driving continuous improvement and innovation.

Challenge: XYZ Automotive struggled with siloed data and communication gaps between engineering and manufacturing teams. This led to errors in production processes and delays in launching new car models.

Solution: XYZ Automotive implemented a comprehensive PLM system. The system centralized product data, streamlined workflows, and enabled real-time collaboration between teams.

Results: XYZ Automotive experienced a 15% reduction in development time, a 10% decrease in manufacturing costs, and a significant improvement in product quality, leading to fewer warranty claims.

A typical product lifecycle can be broadly divided into these stages, with PLM playing a crucial role in each:

1. Planning and Conception: Identifying market needs, brainstorming ideas, and defining product specifications. (PLM facilitates market research, competitor analysis, and capturing initial design concepts.)

2. Design and Development: Creating detailed product designs, engineering prototypes, and conducting testing. (PLM helps manage CAD data, facilitate design reviews, and track revisions.)

3. Manufacturing and Production: Optimizing manufacturing processes, sourcing materials, and managing production lines. (PLM supports bill of materials (BOM) management, production planning, and quality control.)

4. Service and Support: Providing customer service, handling warranty claims, and offering product updates. (PLM enables service manual creation, spare parts management, and product recall coordination.)

5. End-of-Life Management: Planning for product disposal or recycling in an environmentally responsible manner. (PLM facilitates material reuse planning and compliance with environmental regulations.)

Several software solutions are available to help businesses implement PLM. These solutions offer various functionalities like:-

Data management

Workflow automation

Collaboration tools

Product visualization

Document management

Change management

Implementing PLM requires careful planning and consideration. Here are some key steps:

Define Your Needs: Identify your specific product development challenges and how PLM can address them.

Evaluate Software Options: Research different PLM solutions and choose one that aligns with your budget and needs.

Data Migration and Integration: Develop a plan for migrating existing product data and integrating the PLM system with other software tools.

Training and Change Management: Provide training for employees on how to use the PLM system effectively.

PLM is more than just software, it's a strategic approach that transforms how you manage your product's entire lifecycle. By implementing PLM effectively, businesses can achieve significant improvements in efficiency, collaboration, and product quality.

In conclusion, PLM represents a holistic approach to managing product life cycles, offering organizations the tools and strategies needed to drive efficiency, collaboration, and innovation. By adopting PLM, businesses can streamline processes, accelerate time-to-market, and gain a competitive edge in today's dynamic marketplace. As technology continues to evolve and market dynamics shift, PLM remains a cornerstone of success for organizations committed to achieving excellence in product development and lifecycle management.

Modelcam Technologies specializes in providing innovative solutions like Windchill PLM to businesses seeking to optimize their product lifecycle management processes. We are a leading software reseller in Pune. Modelcam plm solutions can transform your business and propel you towards success. Contact us today to learn more about ptc windchill and other plm services that we provide.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.