Choosing the appropriate tools can make the difference between your design journey's success and failure in the fiercely competitive engineering and product development environment of today. Both aspiring engineers and seasoned pros have found Creo Software, created by PTC, to be a reliable and future-ready solution. This 3D CAD software has revolutionized product design workflows with unparalleled speed, accuracy, and flexibility thanks to its potent modules, including Creo Parametric and Creo Simulation.

Creo is the wise investment that yields innovation, efficiency, and results, regardless of your level of experience with complicated design systems. And it's never been simpler to advance from a novice to an expert in Creo thanks to Modelcam Technologies' practical training, installation, and customization services.

Creo Software is a collection of design tools that make it simple for users to create, model, illustrate, and share product designs. Creo provides a smooth workflow from conception to production, serving a variety of industries such as electronics, medical devices, automotive, aerospace, and industrial equipment.

Creo is perfect for engineers that require flexibility and control because it fundamentally makes parametric and direct modeling possible. Users can select particular functionalities, such as 3D CAD software, Creo simulation, or advanced manufacturing capabilities, thanks to the software's versatility.

The foundation of the Creo suite is Creo Parametric. It provides feature-rich, scalable 3D modeling capabilities and provides:

Parametric associative modeling for improved design intent

Automated drawing creation to increase efficiency

Strong assembly control for big-scale models

Smooth interaction with tools for analysis and simulation

Experts like Creo Parametric's flexibility and wide range of customization options, while beginners appreciate its user-friendly interface. Engineers can swiftly advance through the learning curve with the help of thorough tutorials and training assistance from professionals like Modelcam Technologies.

For more understanding, read our blog post, “Top Reasons Why Engineers Prefer PTC Creo Parametric”

A design needs to be validated after it has been modeled. Creo Simulation becomes crucial at this point. Engineers can do static, thermal, and modal investigations with this potent tool without moving data across platforms because it integrates directly within the CAD environment.

Teams may test ideas earlier, iterate more quickly, and save money on physical prototyping by using simulation-driven design. Creo Simulation helps customers create ideal, useful designs, whether the objective is load optimization, thermal performance, or structural integrity.

Decades of engineering brilliance support PTC Creo's trustworthiness. Creo remains at the forefront of product design technology thanks to PTC's dedication to innovation. Modern technologies like Generative Design, AI-driven modeling, support for additive manufacturing, and cloud-based collaboration are among its frequently updated features.

In order to fulfill the unique requirements of contemporary engineering teams, Modelcam Technologies is essential in helping firms with Creo implementation, upgrades, and Creo Toolkit customization.

3D CAD software is essential to any engineering design process. Faster design cycles, increased design accuracy, and simple component and assembly reuse are made possible by Creo's 3D CAD capabilities. Among the main advantages are:

To capture design intent, use parametric modeling.

Direct modeling for fast editing of geometry

Cutting-edge sheet metal and surfacing design

Motion analysis and limitations at the assembly level

Engineers can swiftly move from 2D sketches to 3D parametric models with Modelcam's organized training modules, reducing rework and speeding up time-to-market.

Creo Software is currently using AI-driven capabilities to advance intelligent design features in light of AI's increasing impact in business. Predictive analytics and generative AI (artificial intelligence) are being used to:

Provide the best possible design options

Cut down on material waste

Prior to physical testing, anticipate performance concerns.

Quicken iterations of the product

By incorporating business intelligence into the engineering process, these features facilitate data-driven decision-making. By assisting businesses in integrating these tools, Modelcam makes sure that commercial and engineering goals coincide for optimal effect.

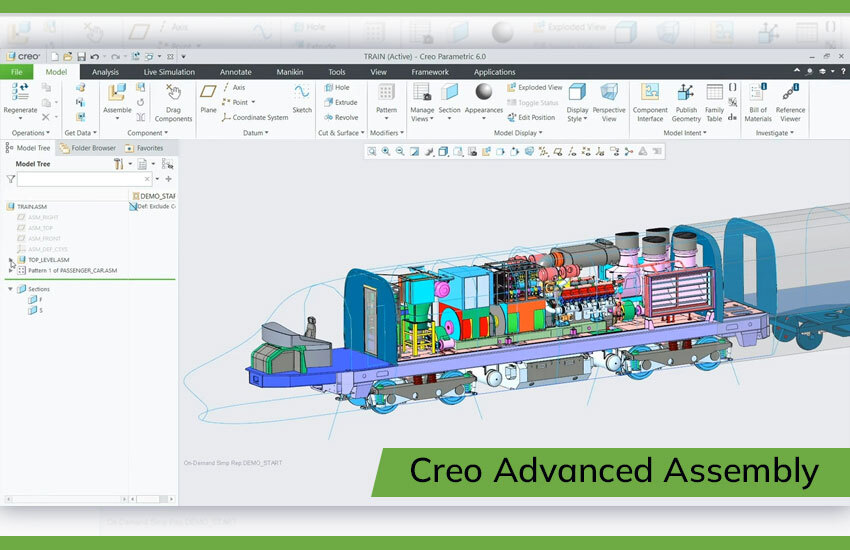

With Creo Advanced Assembly, engineers can manage large, complex assemblies with ease and efficiency. It guarantees correctness throughout the whole product development process by facilitating top-down design, smooth component integration, and dynamic collision detection. It is a vital tool for system-level design since engineers may minimize errors and streamline processes.

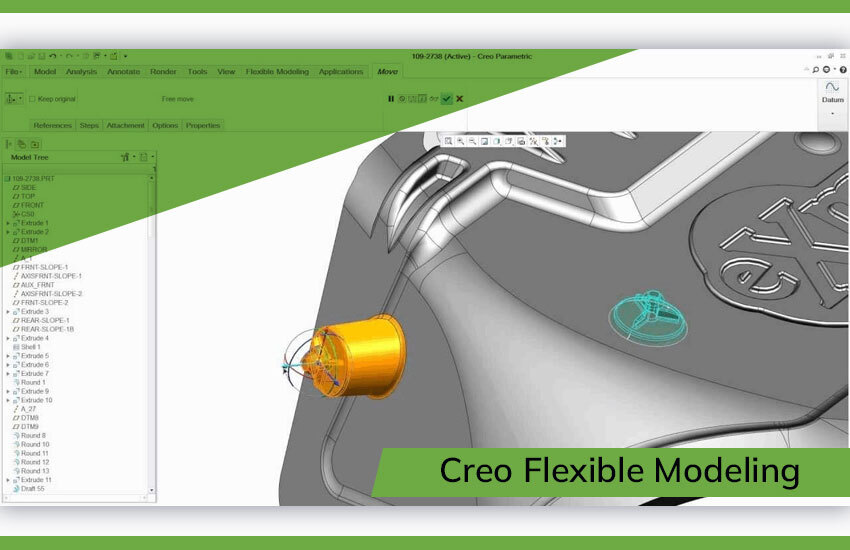

Users can make quick and simple design changes with Creo Flexible Modeling without losing the model's original layout. It's particularly helpful when dealing with imported geometry or in the latter stages of development. This feature improves design agility across teams by bridging the gap between parametric and direct modeling.

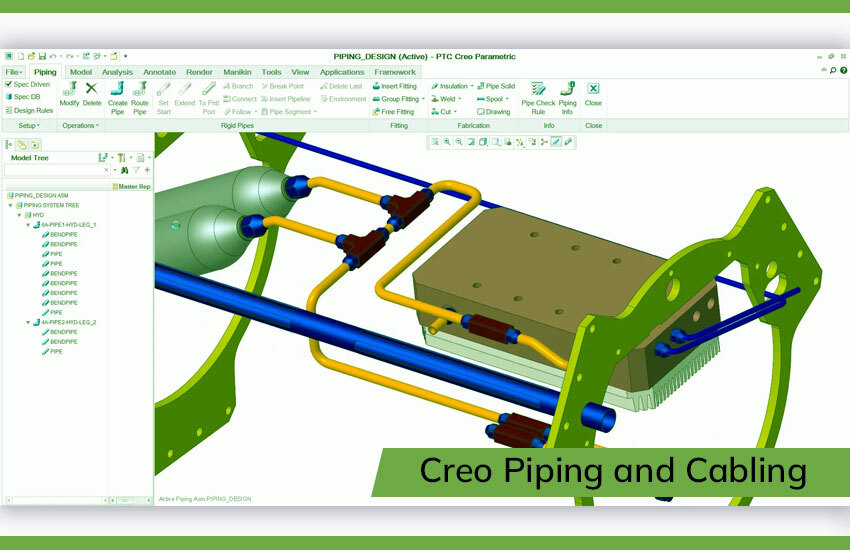

For the purpose of routing and documenting 3D pipe and electrical harness systems, Creo pipe and Cabling was developed. BOMs, flattened drawings for manufacturing, and routing pathways can all be automatically generated by engineers. It facilitates the simplification of intricate wiring and tubing chores in sectors such as industrial machinery, automotive, and aerospace.

Using libraries of prefabricated components and clever placement tools, Creo Advanced Framework Extension (AFX) makes it easier to create intricate structural frameworks. AFX is perfect for architectural and mechanical engineering projects because it increases speed, accuracy, and consistency across design processes, whether creating heavy-duty frames or support structures.

Customer experience and product design are closely related in today's industry. Engineers may better grasp how products are used in the real world with the use of Creo's digital twin and simulation tools, which allow:

Analysis of customer data for customized features

Targeting behavior throughout the design phase

Using smart consumer devices and voice search optimization techniques together

By developing products that cater to particular user needs and preferences, businesses can stand out in crowded markets by using this customer-first design approach.

In addition to design, modern engineering teams also need to handle data and work well together. This is made possible by Creo's smooth PLM system interaction, real-time data synchronization, and data automation processes.

These features enable companies to grow without sacrificing control or quality. Design and procurement are accelerated when engineers have immediate access to supplier data, revision history, and parts libraries. Businesses who use Creo, which is powered by AI and data analysis, also gain from:

Saving money on testing and prototyping

Reduced consumer complaints and design flaws

Shorter timeframes from design to manufacturing

Creo offers the adaptability and depth to fit your project scope and career level, whether you're a manufacturing specialist, aspiring design engineer, or product manager. For these reasons, it's a prudent investment:

User-friendly Interface for Novices: New users can become production-ready in a matter of days with training from partners such as Modelcam.

Scalable for Experts: It can handle the most intricate assemblies and simulations thanks to its sophisticated modules and customization options.

Future-Proof with AI: To satisfy the requirements of Industry 4.0, Creo consistently integrates predictive analytics and AI-driven solutions.

Customer-Centric: Products gain a competitive edge from features that facilitate real-time feedback, behavioral design patterns, and customer data analysis.

By collaborating with Modelcam Technologies, you can get access to a team that is an expert in Creo. Whether your team needs training on the Creo Toolkit, Creo Parametric, or Creo Simulation, Modelcam makes sure they have the resources and know-how to be successful.

Personalized training, webinars, and workshops may help you transform your technical staff into power users. In order to make sure your CAD investment grows with your company, they also offer automation scripting, PLM integration, and AI enhancements.

For engineers at every point of their careers, Creo Software is a potent ally, offering everything from basic modeling to sophisticated simulations and AI-driven design automation. The platform provides unparalleled value, variety, and speed with powerful tools like Creo Parametric, PTC Creo, and 3D CAD software.

You can fully utilize Creo Simulation, effectively integrate product design tools, and provide outstanding results on every project by working with professionals like Modelcam Technologies. Creo is the solution if you're searching for a wise, scalable, and future-proof investment.

Are you prepared to improve your engineering skills? Discover Creo with Modelcam now to revolutionize your design, innovation, and delivery processes.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.